NIT launches WiDy SenS GigE for industrial applications

NIT launches a new SWIR camera on June 25th. The WiDy SenS GigE, with a proven standard interface, for industrial applications.

Welcome to our product launch event.

Today we gonna introduce to you our new product: the WiDy SenS GigE.

Program

Our event includes:

- Introduce new features and advantages

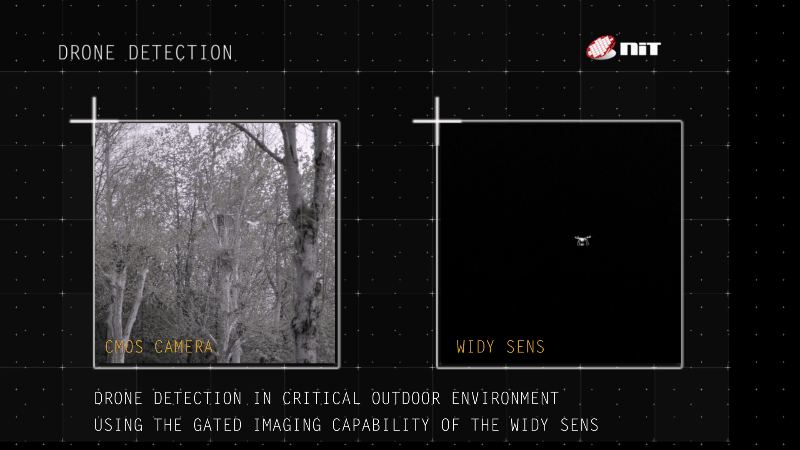

- Demonstrate camera performance

Product

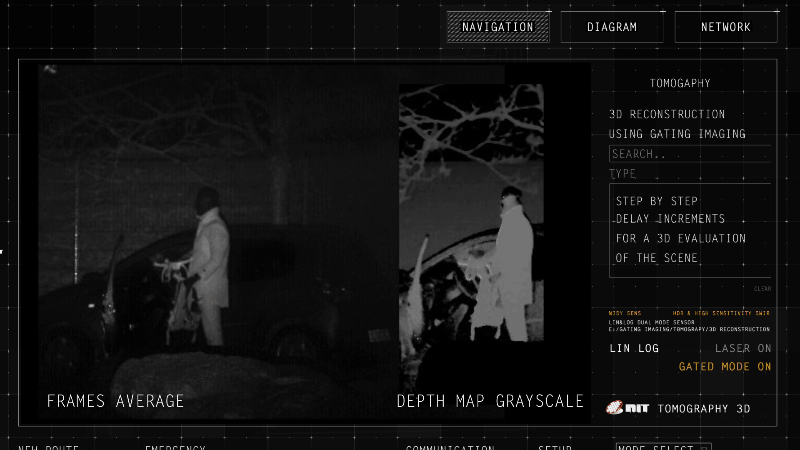

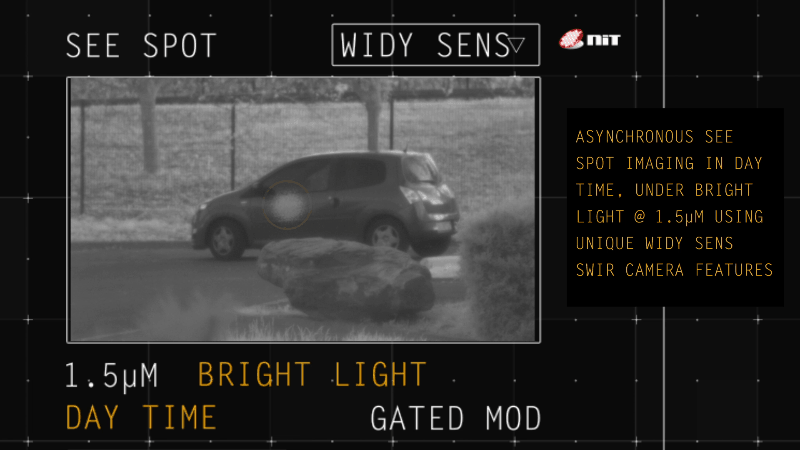

The New WiDy SenS GigE is a VGA SWIR Camera. The camera integrates NIT flagship Sensor NSC1601, with Dual-Mode.

It provides an image of 640 x 512 pixels, with a very High Dynamic Range of 120dB (for high flux scene and a high sensitivity mode with a readout noise of 50e-).

This WiDy SenS GigE features a Gigabit Ethernet output & a brand-new Hirose connector. This connector combines power supply and Triggering inputs/outputs options.

With a complete SDK compatible with Windows or Linux, the WiDy SenS GigE is a perfect SWIR option for easy integration into industrial equipment.

Applications:

The WiDy SenS GigE has been designed to meet the requirements of new industrial applications with a proven standard interface.

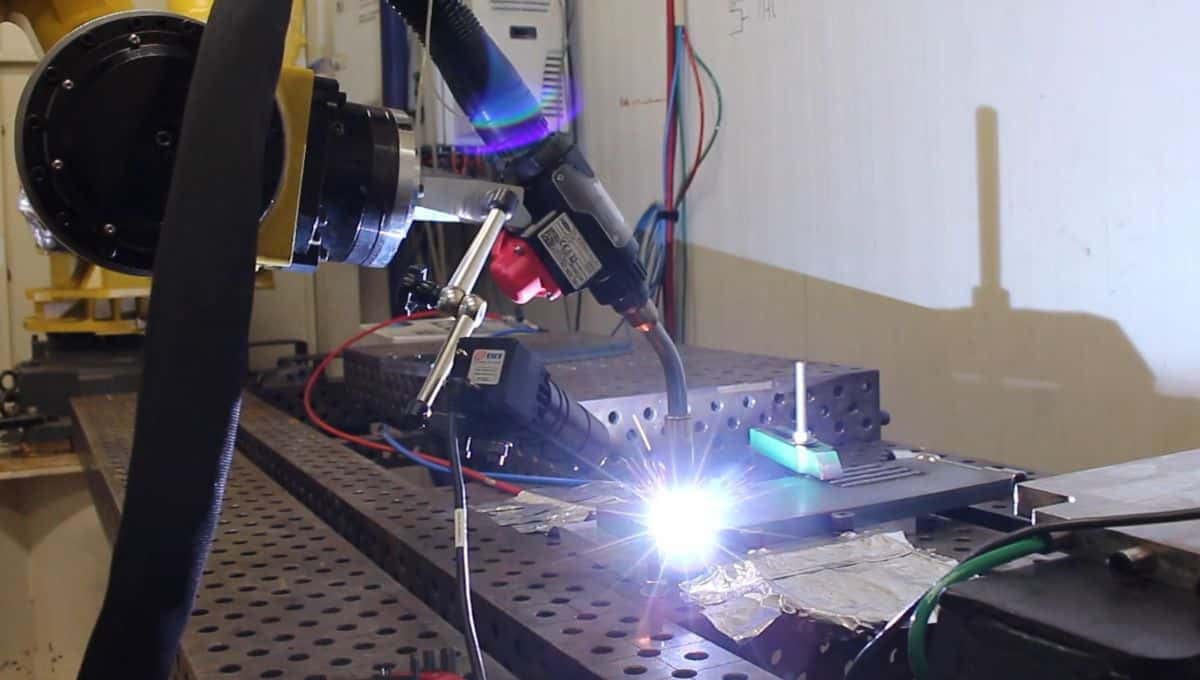

Major applications include Semiconductor inspection/ Wafer inspection, but also new emerging applications, such as Monitoring of Additive manufacturing or even Sorting machines.

NIT SWIR cameras

The WiDy SenS completes the existing NIT SWIR products line – WiDy family:

- The WiDy SWIR cameras, providing the high dynamic range in USB, CameraLink & GigE.

- The WiDy SenS cameras, (HDR and High sensitivity) in USB, CameraLink & GigE.

- The WiDy NaNo, with an impressive form factor, providing HDR images and a USB3.0 form factor.

It is officially available through NIT sales channels and with a short lead time.

Thank you for joining us.

See you in our next innovation!

MERCI!