Semiconductor inspection

Inspection has become one of the key processes in the semiconductor industry: Detecting defective items along the production line helps to improve yields and the overall productivity of one of the biggest industry.

SWIR

SWIR line-scan

Demonstration videos

why NIT?

Recommended products

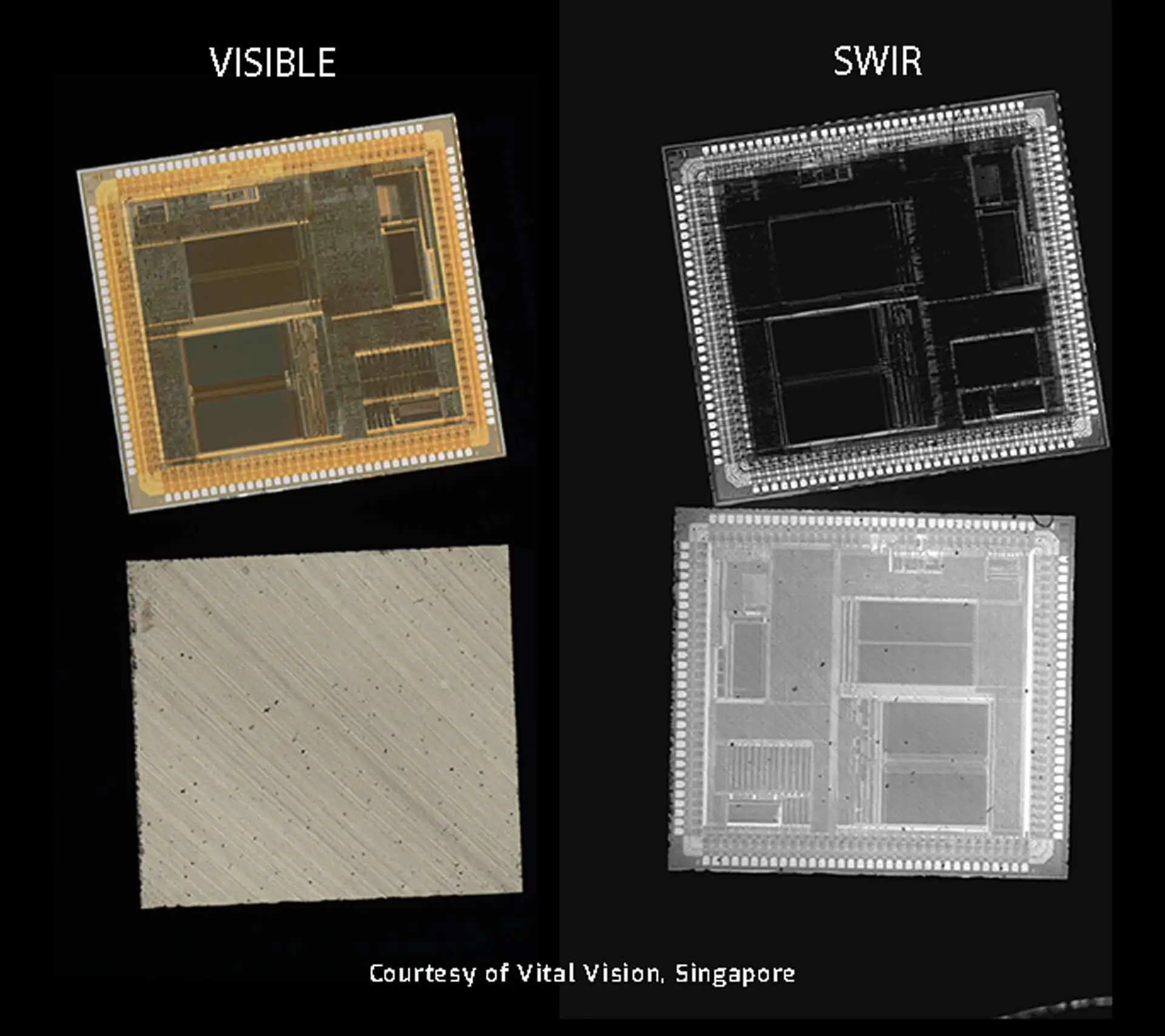

SWIR – Reveal the heart of your material

For the past years, the SWIR band has been recognized as one of the best wavelength regions for semiconductor inspection. Whether it is for detecting cracks and defect on a wafer or solar cell panels, or for achieving a failure analysis of integrated circuits, InGaAs wavelength (900m- 1700nm) imaging device are suited for seeing through inside silicon.

Moreover, NIT SWIR imaging devices offer an attractive performance/price ratio when it comes to ease the integration into semiconductor production lines.

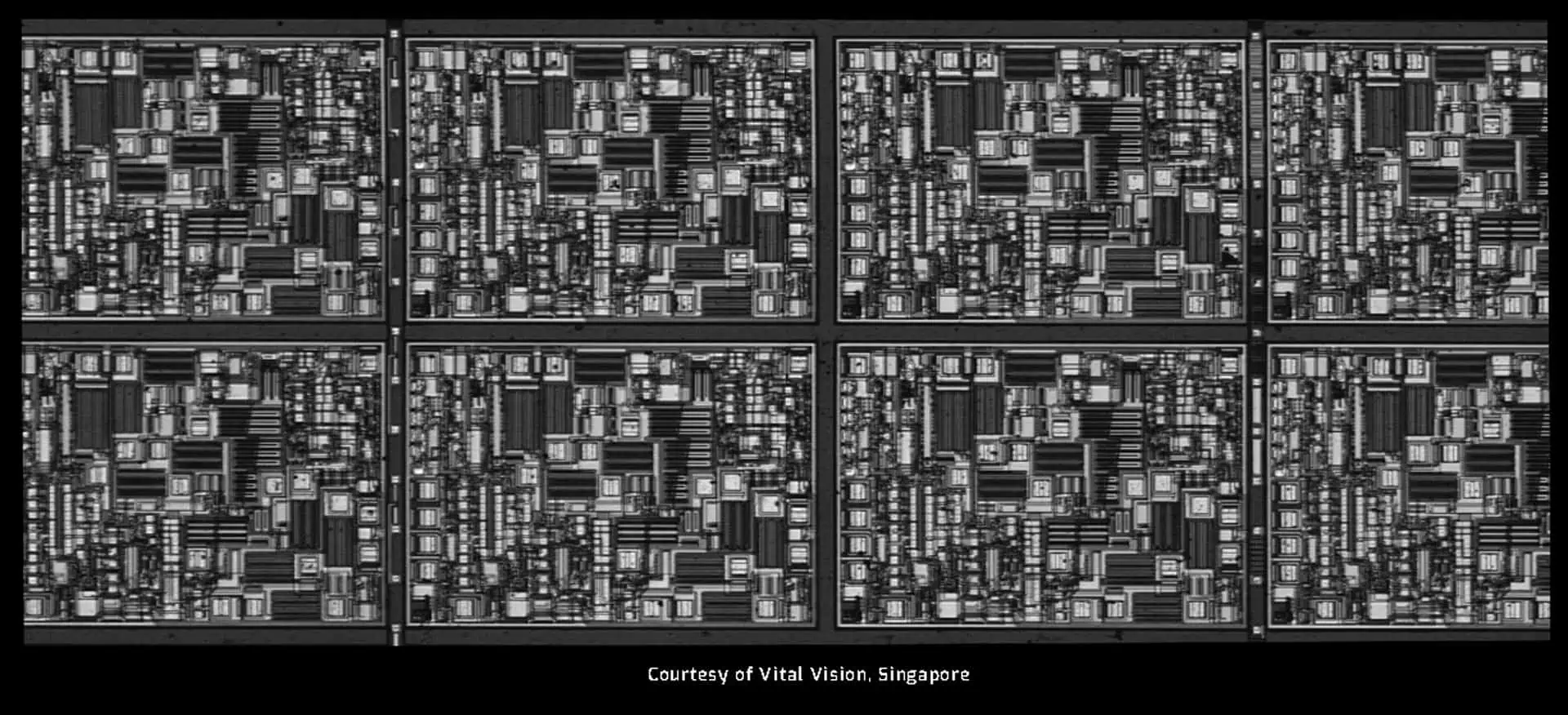

LiSaSWIR – The Ultimate Tool for Electronic Components, Silicon Wafers, and Solar Panels Inspection

Lisa SWIR was specially developed for semiconductor inspection, with the ability of SWIR wavelength to see through silicon. Inspection of silicon wafers or of single dies can be easily set up.

The solar panel both at production and on-site can be inspected by Lisa SWIR providing extremely accurate images of photoluminescence induced by small defects even at low contrast.

Thanks to its small pixel size of 7.5um, Lisa SWIR procures extremely sharp and crisp images of defects in materials at high throughput.