HiPe SenS CameraLink – Now available

NIT expands the High-Performance SWIR camera series with the HiPe SenS CameraLink.

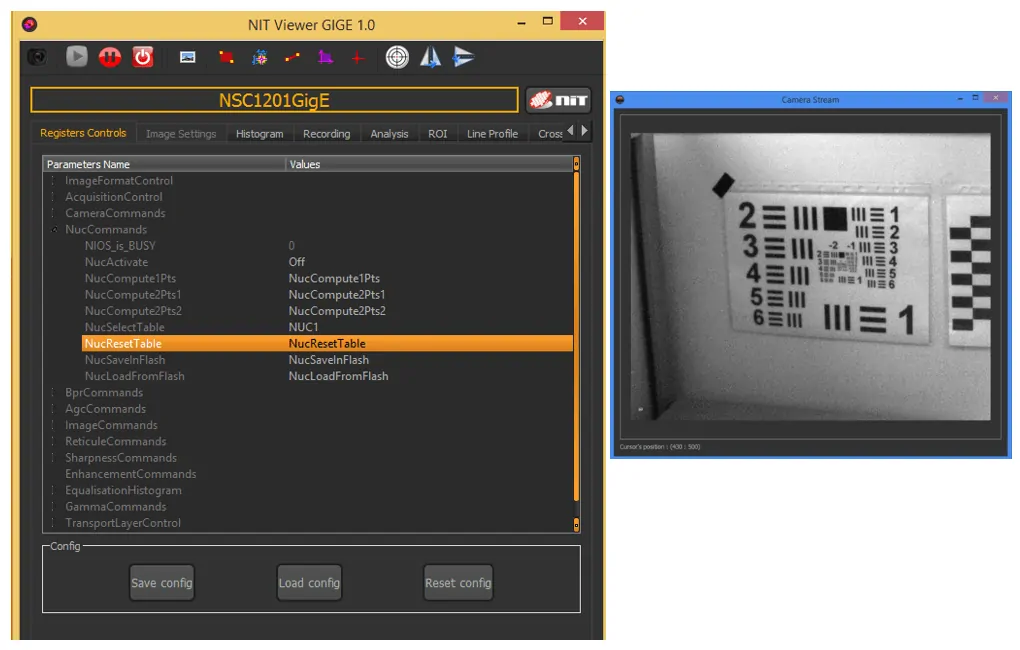

To facilitate the integration of HiPe SenS cameras into any microscopy or system, NIT provides one more option from the HiPe SenS series. This camera with CameraLink interface is delivered calibrated with proprietary WiDyCAM software.

SWIR Microscopy application

Explore how SWIR cameras, particularly NIT HiPe SenS, bring benefits for low light and long exposure time applications (Microscopy, Biomedical, Semiconductor Inspection, etc. )

The HiPe SenS 640M-ST, like the USB3.0 version, features the latest NIT’s SWIR sensor NSC1902T along with TEC2 and air-cooled mode, low sensor noise 40e-, ultra-high sensitivity – so the most demanding projects for low light and long-exposure time applications can be achieved easily.