Welding plays a vital role in various manufacturing industries as it enables the assembly of metal parts with precision and strength. More importantly, visualizing the welding processes has proven crucial in enhancing the quality and efficiency of welding operations. In this blog post, we will explore the benefits of clearly monitoring welding processes and explain how Short Wave Infrared (SWIR) cameras are invaluable.

Importance of Welding in Manufacturing Industries

Welding has been a key technology in the manufacturing sector, enabling the fabrication of diverse metal components. As industries continuously strive for improved quality and productivity, welding processes have become more sophisticated and automated. To ensure assembly consistency, reproducibility, and quality, it is essential to visualize and monitor the weld pool, especially considering the challenging conditions posed by high temperatures, intense light, and significant contrasts.

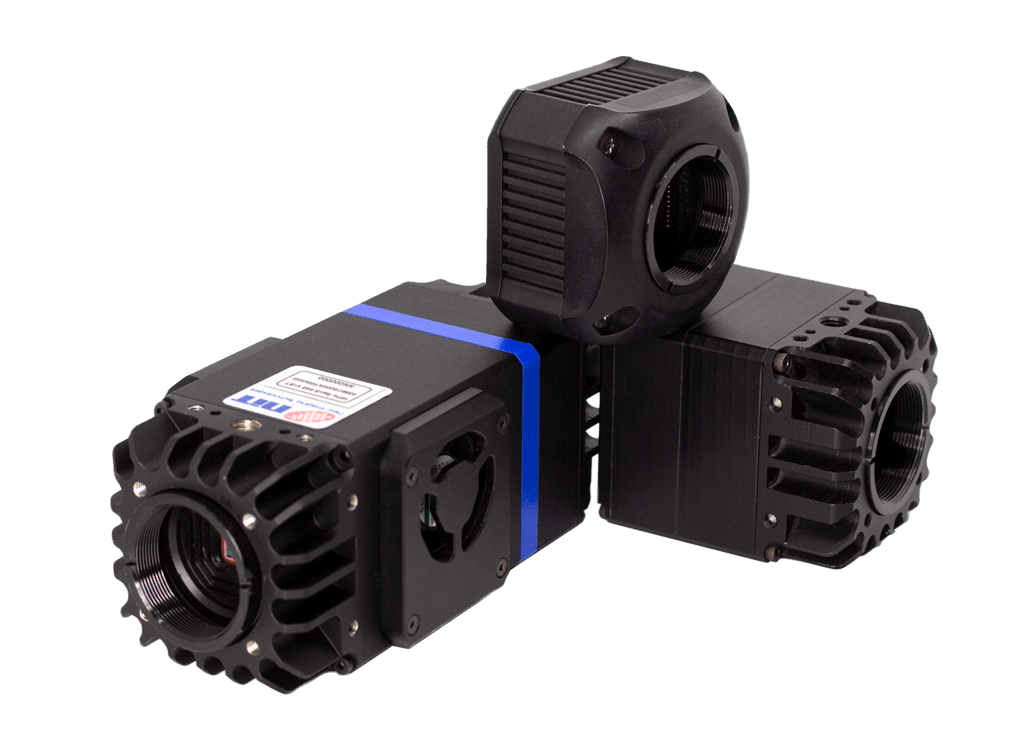

What are Short Wave Infrared Cameras?

Short Wave Infrared (SWIR) cameras operate in the wavelength range of 0.9 to 1.7 microns, which is beyond the scope of human vision. These cameras offer superior imaging capabilities compared to visible light cameras under specific conditions. One advantage is their high dynamic range, allowing them to capture both the welding arc and the bevels in a single image without the need for filters. SWIR cameras provide high-contrast, clear images of the welding arc, melting bath, and surrounding material, enabling enhanced visualization of welding processes.

For a more in-depth explanation of SWIR cameras, read our previous blog post: How Do SWIR Cameras Work?

The Use of SWIR Cameras in Welding

SWIR cameras provide high-quality imaging of the welding arc, melting bath, and surrounding material, facilitating process control and quality assurance. With their compatibility across various welding processes and applications in additive manufacturing and thermal imaging, SWIR cameras have become indispensable in the welding and manufacturing industries. As technology continues to advance, these cameras hold immense potential for further innovations in the field of welding visualization.

Some of the benefits of SWIR cameras include being able to image through fumes and smoke in challenging environments, which is difficult or impossible with other techniques. They are also compatible with various glass optical filters that can withstand harsh welding conditions and produce high-resolution images ideal for monitoring high-precision processes.

Visualizing Welding Processes with New Imaging Technologies

New Imaging Technologies (NIT) is a renowned company that designs and manufactures image products based on patented high-dynamic range response sensors. The SWIR cameras we offer deliver exceptional image quality, ensuring the precise monitoring of welding operations.

For visualizing welding processes, we recommend the WiDy SenS 640 SWIR camera. It is a unique dual-response InGaAs sensor with high sensitivity and an HDR camera designed to provide a VGA resolution of 640x512px for a wide field of view. The WiDy SenS is commonly used as a beam diagnostic tool in additive manufacturing processes such as welding.

SWIR imaging solutions

Contact NIT today for more information about our SWIR imaging solutions and Welding application.