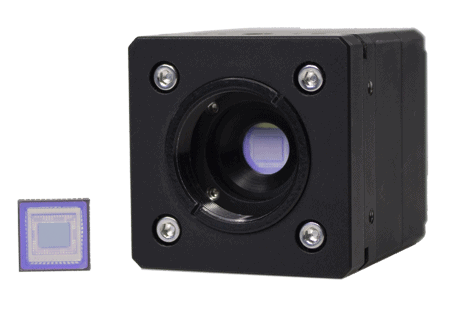

NSC2001 is the NIT Triple H(*) SWIR sensor:

- High Dynamic Range operating in linear and logarithmic mode response, it exhibits more than 120 dB of dynamic range

- High Speed, capable of generating up to 1K frames per second in full frame mode, and much more with sub windowing

- High Sensitivity and low noise figure (< 50e-)

| Features | Benefits |

| Pixel size 15×15µm | Optimum pixel size for high-speed operation without sacrificing sensitivity |

| Resolution 320×256 pixels | The ideal format for achieving a low price point |

| Noise level <50e- | Capture low-light-level events |

| TEC-less operation | Low power consumption |

| Linear and Logarithmic Response | The high dynamic range available, ideal for laser and high photon flux application |

| Frame rate 1KHz | Allow capturing fast transient phenomena |

NSC2001 fully benefits from NIT’s new manufacturing factory installed in our brand-new clean room, which includes our high-yield hybridization process. Our new facility allows us to cover the entire design and manufacturing cycle of these sensors in volume with a level of quality never achieved before.

Moreover, NSC2001 was designed with the objective of addressing new markets that could not invest in expensive and difficult-to-use SWIR cameras. The result is that our WiDy SenS 320 camera based on NSC2001 exhibits the lowest price point on the market even in unit quantity.

Typical applications for NSC2001 are optical metrology and testing, additive manufacturing, welding, & laser communication, etc.

(*) Triple H is now a retired professional wrestler. He was widely regarded as one of the greatest professional wrestlers of all time

Interested in the NSC2001's performance?

Schedule a demo with application advice to test the WiDy SenS 320 now