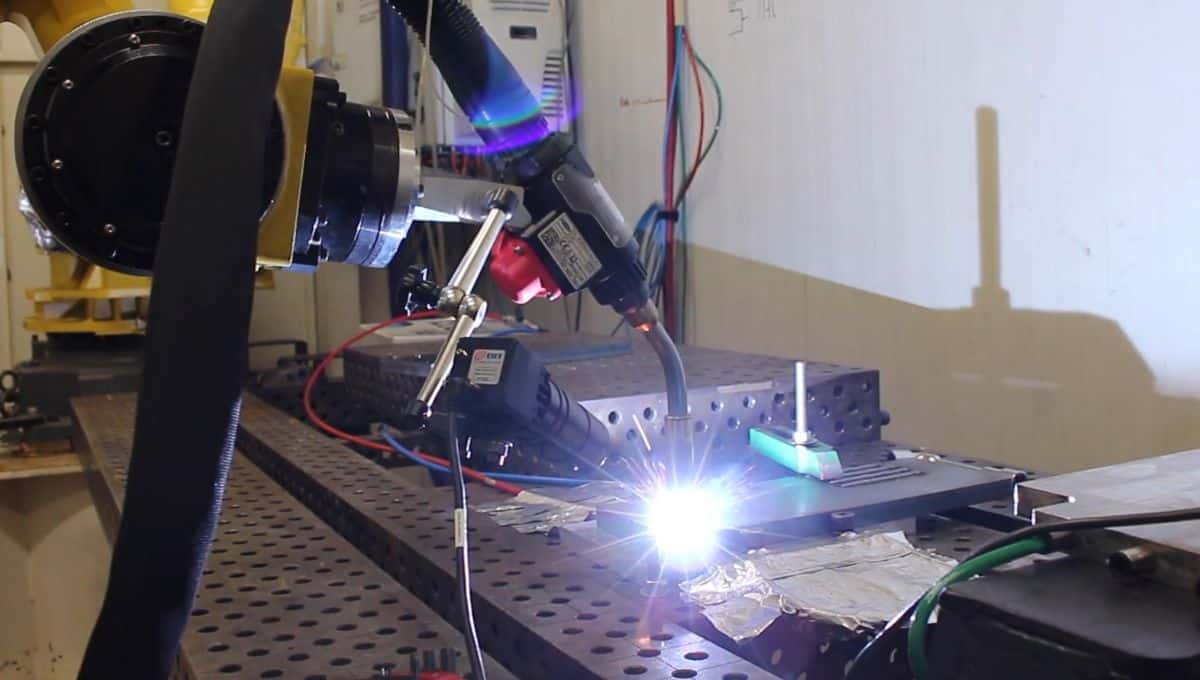

NIT Additive Manufacturing demo including WAAM and Laser Additive Manufacturing.

See the melt-pool and its hydrodynamics like never before!

A better definition of the melt-pool

To summarize why the WiDY SWIR camera is the perfect ally for Additive manufacturing process, we are glad to bring you our demonstration video.

This is the result of our collaboration with the Institut Maupertuis -a French technological center specialized in automated production technologies.

Through this test, we illustrate how our SWIR camera – WiDy SenS performs in very high flux scenes of the melt pool in Wire Arc Additive Manufacturing (WAAM) and Laser Additive Manufacturing processes:

- True shape and geometry of the Melt pool without blooming effect

- The temperature gradient and flow dynamics with SWIR wavelength.

Additive manufacturing case study

If you are interested in our anti-blooming technology for industrial applications and our SWIR products, we are always here to discuss more.

Related products

- WiDy SenS camera – NSC1601T-SI

- MAGIC camera – MC1003