Join us at FABTECH 2019 – booth#A3742 from November 11-14 to experience our cameras in action in the Welding & Additive Manufacturing industry:

- Logarithmic CMOS camera – MC1003 (140dB) – acclaimed HDR visible camera for monitoring process.

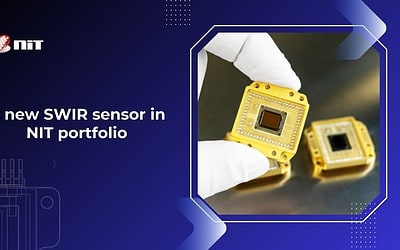

- HDR + TEC SWIR camera – WiDy SenS (120dB) – the perfect ally for Additive manufacturing analysis, control, and process optimization.

No need to use any good-looking words to describe our technology, judge by yourself through our video demo here.