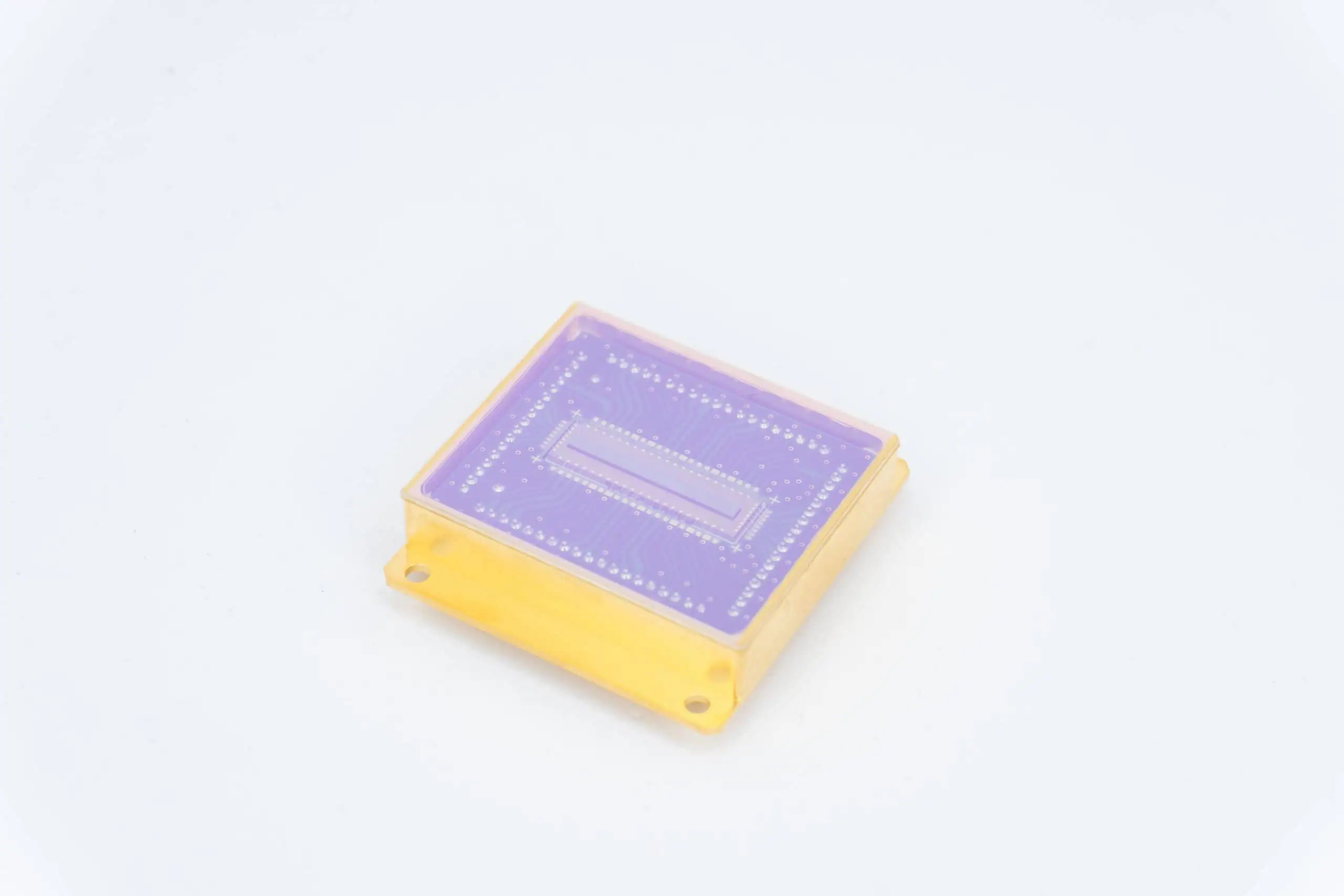

LiSaSWIR 2048

Line-scan array SWIR camera

Version 2 - NEW

- Line-scan array featuring NIT’s NSC2301 sensor, designed and manufactured by NIT

- 2K resolution – 2048x1px @8×14 µm or Rectangular pixel 8×200µm pixel size

- Frame rate >110kHz Full resolution

- High Sensitivity, Low noise <90e-

- High Dynamic Range

- CameraLink interface

- GenICam compliant

The LiSaSWIR 2048 v2 is a next-generation SWIR line-scan camera designed for high-speed, high-precision inspection applications. Powered by NIT’s new NSC2301 InGaAs sensor, this upgraded model delivers significant advancements in sensitivity, image quality, and integration flexibility.

With 2048 pixels and an 8 µm pixel pitch, the LiSaSWIR 2048 v2 offers excellent resolution while maintaining compatibility with standard 1.1” format lenses. The camera supports line rates > 110 kHz, configurable exposure times, and both ITR and IWR readout modes, enabling it to adapt to fast-moving scenes and varying object speeds.

Key performance improvements of the NSC2301 sensor include enhanced uniformity, lower noise, reduced dark current, and refined gain control—critical for demanding industrial environments. Additional onboard features, such as Non-Uniformity Correction (NUC) and Bad Pixel Replacement (BPR), ensure reliable and consistent imaging performance.

Thanks to its compact form factor and industry-standard CameraLink interface, the LiSaSWIR 2048 v2 integrates easily into existing inspection systems.

Typical applications include:

- Semiconductor and photovoltaic inspection

- Food and vegetable sorting

- Waste management and recycling

- Pharmaceutical packaging and process control

Technical Specification

| Sensor | NSC2301 |

| Material | InGaAs |

| Resolution | 2048x1 |

| Pixel size | 8x14μm | 8x200µm |

| Spectral response | 0.9 to 1.7μm |

| Response | Linear (Low, Medium & High Gain) |

| Modes | ITR, IWR, ROI |

| QE | >80% |

| Frame rate | >110kHz full frame |

| Exposure time | Minimum Integration time: 1µs

Controlled by camera register or Trigger width |

| Triggger | Internal/External (LVTTL) Software Trigger Trigger over Cameralink |

| Trigger delay | User-Selectable |

| Partial reading mode | Region of Interest (ROI).

User-selectable with a step of 8 pixels. Maximum FPS increase with reduced ROI. |

| Read-out noise | • High gain (CDS): <90𝑒− • Medium: < 370𝑒− • Low: <2200𝑒− |

| Dynamic Range | •High gain (CDS): 55dB typical •Medium: 62dB typical •Low: 66dB typical |

| Control | Genicam / GenCP |

| Output type | Cameralink base 8/10/12/14 bits pixel formats. Configurable output geometry: 1X_1Y / 1X2_1Y / 1X3_1Y |

| Power consumption |

|

| Operating temperature | -40 to +71°C |

| Size (WxHxL, mm) | 45.4 x 75 x 58mm |

| Weight | 280g |

| Lens mount | C-Mount |

| Control protocol | GenCP (Genicam) compliant |

| NIT Software | NITGenicamControlTool (Windows, camera control only) |

Applications

With its unique performance and features, the LiSaSWIR 2048 is the perfect camera for industrial applications.

- Solar panel inspection/ Semiconductor Inspection

- Process sorting

- Hot Glass inspection

- Waste sorting