WELDING & ADDITIVE MANUFACTURING

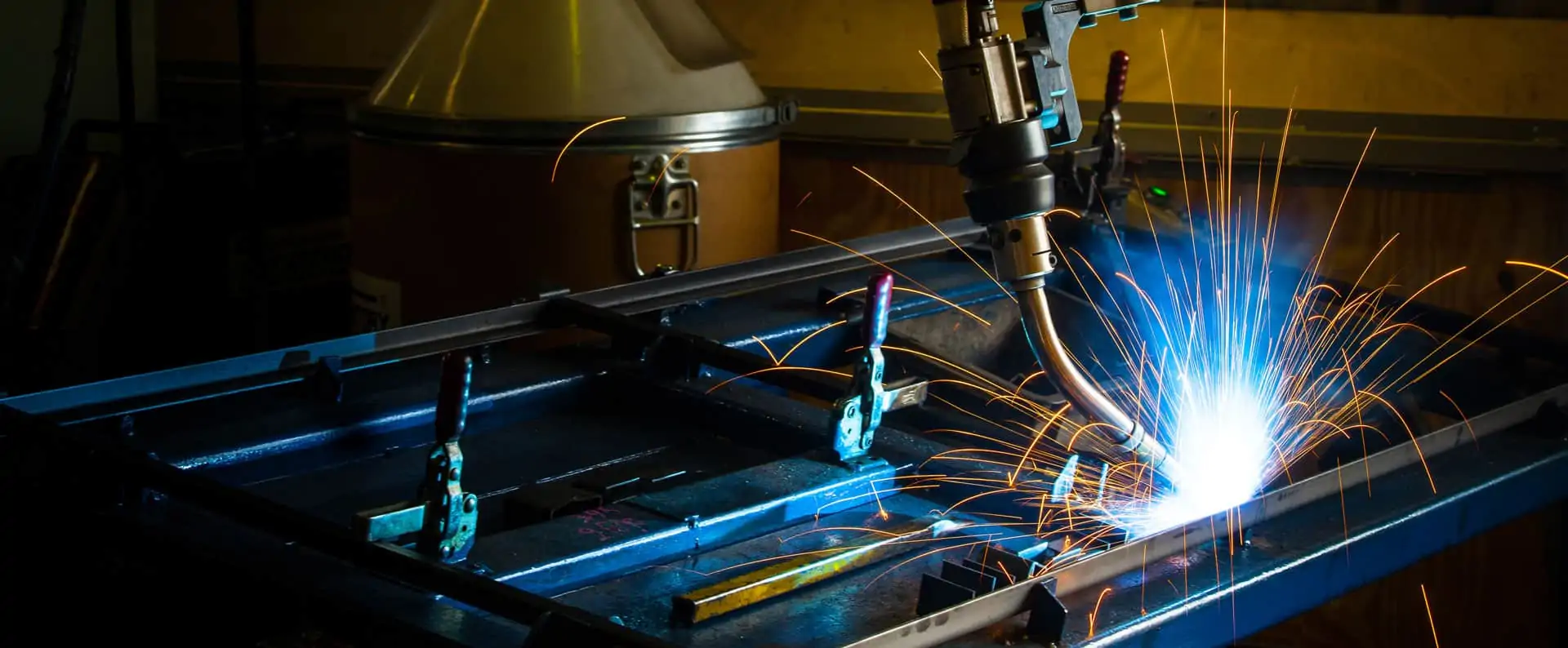

Achieving better goods quality and yield through vision has now become widely used for manufacturing industries. The welding and more recently, the additive manufacturing processes, are now massively adopting cameras for inspecting parts or monitoring processes. Characterized by extremely high illumination with strong contrast, smoke and dust, and various of the process (TIG, MIG – MAG, YAG,…) imaging welding has always been a challenge. With long set-up efforts including neutral density filter use, trade off on exposure time, people have been able to visualize processes but they are still lacking important details due to the low Dynamic Range of existing cameras.

HDR

Demonstration videos

why NIT?

Recommended products

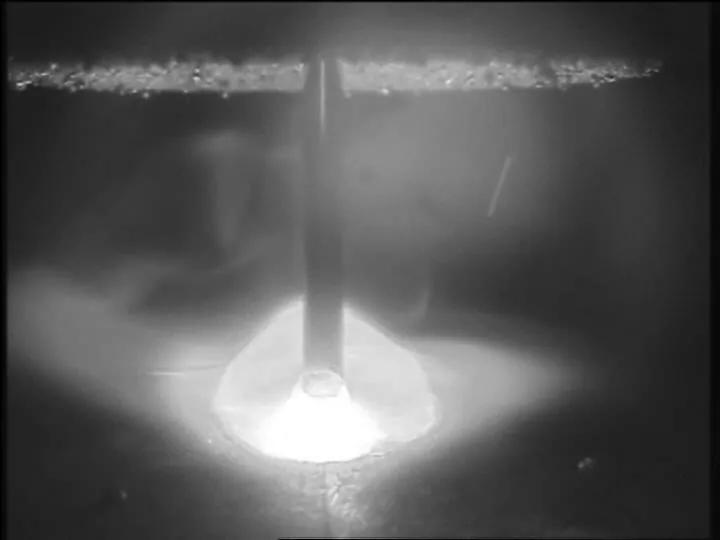

High Dynamic Range: Discover what you can’t see!

The NIT MAGIC CAMERAS solves this lack of efficiency and robustness by offering high-quality images of the melt-pool, without any saturation and disturbing circle of light. Filters are not necessary anymore. Thanks to the native High Dynamic Range of the product – up to 140 dB or 120dB for the SWIR products – the welding arc, as well as the bevels, can be seen in the same time in one single image. All the relevant parameters can be monitored without any image processing.

The use of our SWIR Camera, WiDy SenS, brings even more valuable information for additive manufacturing processes thanks to the Infrared band, i.e: 900nm-1700nm. Temperature homogeneity and geometry of the melt pool could be then monitored.

Demonstration videos

Why NIT?

High Dynamic Range (120dB - 140dB)

Visible or SWIR wavelength for additive manufacturing

Easy to integrate into any system

Software & SDK compatible with multiple environments

Recomended products

SWIR

- 640x512px (VGA) @15μm pixel pitch

- HDR 120dB + High Sensitivity

- USB 3.0/CameraLink /GigE/Analog/SDI

CMOS

- 1280 x 1024px – 6.8μm – Color or B&W

- HDR 140dB

- USB 3.0/ CameraLink/ GigE